Reasons Why Your Business Should Use CNC Machining Services

If you want to have something manufactured, you have many different options. You can choose to have it laser cut, hand created, stamped, or machined. CNC milling offers the best alternative for those who are looking for truly precise, high-quality parts. In this guide, we’ll explore why your business needs to use CNC machines.

They Result in Highly Accurate Components

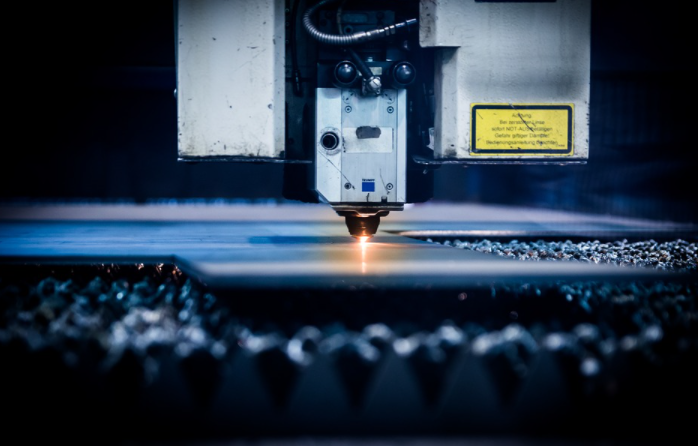

Many CNC manufacturing methods work in two ways. Today’s most popular way is to use a CNC punch press or even a CNC laser cutter. These two can cut parts from a flat metal plate. This allows you to make precise parts, but you have no control over the depth of that sheet. The depth of this plate can vary across the entire plate. This makes it difficult to cut exactly the same part, even if it is cut from the same sheet metal. This way, every single dimension of the item can be created to exact specifications.

They Combine Laser Cutting With Machining Technique

CNC machining is a simple fact that it can be quite expensive. A less expensive option is to laser cut the part. The part can be cut a few millimeters larger than needed, and the machine tool can go around the outside of the profile to make sure it fits within the important dimensions. For example, cutting a 12 mm piece of sheet metal and then reducing it to 10 mm with a machining center is easy and results in an accurate part that is less expensive than cutting the entire part by machine.

They Produce High-Quality Finishes

It is vital to produce high-quality surfaces. There will be no distortion caused by excess heat when cutting the product. This manufacturing technique also leaves a completely clean edge with no streaks or damage to the fabric. Anyone interested in acquiring high-quality, precision components should consider machining as their preferred manufacturing method. It is ideal for producing interlocking gears or high-precision parts for the healthcare industry.

They Generate Professional Teams and the Most Recent Software

Typically, manufacturers use the latest software applications to control tools to their specifications. In addition, their teams are proficient and can use many different tools to get the most out of cutting range, tight tolerance, and surface finish. Therefore, they can meet your design needs. Simply put, CNC machining offers several advantages over other processes. That’s why most manufacturers are turning to this technique. Today, this strategy is well known in the manufacturing market.

And it’s being used for a variety of products for a whole host of reasons, such as cost efficiency, faster turnaround time, and greater accuracy, to name a few. Therefore, these types of machines are a good choice for different types of materials. Try to find a reputable and well-known machining company that can produce excellent parts in the shortest time possible. CNC machine tools can dramatically increase your productivity. All manufacturing companies will use CNC tools to be more competitive. So why shouldn’t you do the same?…

First impressions don’t matter in today’s world – you need to make a lasting impression to keep people coming back to you. Whether it’s a potential employee, client or customer, the way your workspace feels and is positioned reflects the way you run your business and your work ethic. If you promote loyalty and tenacity, your furniture should opt for a modern look that can only be achieved with the ideal office furniture.

First impressions don’t matter in today’s world – you need to make a lasting impression to keep people coming back to you. Whether it’s a potential employee, client or customer, the way your workspace feels and is positioned reflects the way you run your business and your work ethic. If you promote loyalty and tenacity, your furniture should opt for a modern look that can only be achieved with the ideal office furniture.

The next significant thing to do is to find out and choose the ring shape and design that she loves. The shape of the diamond is crucial, as it indicates that the actual geometry of the rock, rather than this cut, refers to the angles of these aspects of the rock. You will find quite a few stone shapes to choose from.

The next significant thing to do is to find out and choose the ring shape and design that she loves. The shape of the diamond is crucial, as it indicates that the actual geometry of the rock, rather than this cut, refers to the angles of these aspects of the rock. You will find quite a few stone shapes to choose from.

Pareto charts are very similar to histograms or bar graphs, regardless of whether the Pareto study reflects the 80:20 rule. The 80:20 rule was originally proposed by Vilfredo Pareto’s study and states that 80% of a nation’s wealth belongs to only 20% of its inhabitants. This ratio is as important in business as it is in economics. This analysis allows us to focus our resources on the crucial few to gain maximum advantage.

Pareto charts are very similar to histograms or bar graphs, regardless of whether the Pareto study reflects the 80:20 rule. The 80:20 rule was originally proposed by Vilfredo Pareto’s study and states that 80% of a nation’s wealth belongs to only 20% of its inhabitants. This ratio is as important in business as it is in economics. This analysis allows us to focus our resources on the crucial few to gain maximum advantage.

though you may love music, it takes a little more to deliver beautiful songs with your voice. Some people have a natural born ability to do this, but there are those who need some help in controlling their voice, and this is where a vocal coach can contribute.

though you may love music, it takes a little more to deliver beautiful songs with your voice. Some people have a natural born ability to do this, but there are those who need some help in controlling their voice, and this is where a vocal coach can contribute. One way of identifying a good singing instructor is to see how they have structured their lessons. There must be gradual and relaxed steps to help a student improve the quality of their voice. Any student will learn well if the instructions are given in a manner that makes them want to learn and improve themselves.

One way of identifying a good singing instructor is to see how they have structured their lessons. There must be gradual and relaxed steps to help a student improve the quality of their voice. Any student will learn well if the instructions are given in a manner that makes them want to learn and improve themselves.

Collagen has been lauded to be significant in the formation of elastin which is essential in maintaining an appealing skin with a good texture, youthful tone, and beautiful appearance. Collagen will effectively reduce the visibility of wrinkles that are bound to suffice with age. Also, people dealing with cellulite have lauded the effectiveness of bone broth. Cellulite is caused by the lack of Connective tissue. Collagen enhances your skin’s health by strengthening the reproduction of the Connective Tissue.(CT)

Collagen has been lauded to be significant in the formation of elastin which is essential in maintaining an appealing skin with a good texture, youthful tone, and beautiful appearance. Collagen will effectively reduce the visibility of wrinkles that are bound to suffice with age. Also, people dealing with cellulite have lauded the effectiveness of bone broth. Cellulite is caused by the lack of Connective tissue. Collagen enhances your skin’s health by strengthening the reproduction of the Connective Tissue.(CT)

One needs to ask for a written estimate of the work that needs to be done. Professional contractors will have a team analysis the work that needs to be done and give a written estimate. They will also include what time they will need to do the job and warranty policies.…

One needs to ask for a written estimate of the work that needs to be done. Professional contractors will have a team analysis the work that needs to be done and give a written estimate. They will also include what time they will need to do the job and warranty policies.…

arts off when the team has a meeting with the coordinator or game master. He or she explains rules of the game and briefs participants what is expected of them. In some cases, there is a backstory to the theme and participants may get an opportunity to see the video.

arts off when the team has a meeting with the coordinator or game master. He or she explains rules of the game and briefs participants what is expected of them. In some cases, there is a backstory to the theme and participants may get an opportunity to see the video. articipants should look for puzzles. If you find one, then you will need to solve it. By solving just one, you may not get to the required destination. As time moves on, complex puzzles starting coming over. In the end, there is one puzzle that offers players the code or key to open the door and escape.

articipants should look for puzzles. If you find one, then you will need to solve it. By solving just one, you may not get to the required destination. As time moves on, complex puzzles starting coming over. In the end, there is one puzzle that offers players the code or key to open the door and escape.

the Visa program. This means it is an application for all travelers coming from Visa Waiver countries including the UK. This program has simplified travel to the US for many travelers by only requiring them to have an e-passport. However, due to heightened security measures, you must first apply for ESTA in advance before traveling. Also, an e-passport is still required to gain entry into the US. The whole application process is done online through the Department of Homeland Security.

the Visa program. This means it is an application for all travelers coming from Visa Waiver countries including the UK. This program has simplified travel to the US for many travelers by only requiring them to have an e-passport. However, due to heightened security measures, you must first apply for ESTA in advance before traveling. Also, an e-passport is still required to gain entry into the US. The whole application process is done online through the Department of Homeland Security. For you to apply for ESTA, you must fill in

For you to apply for ESTA, you must fill in